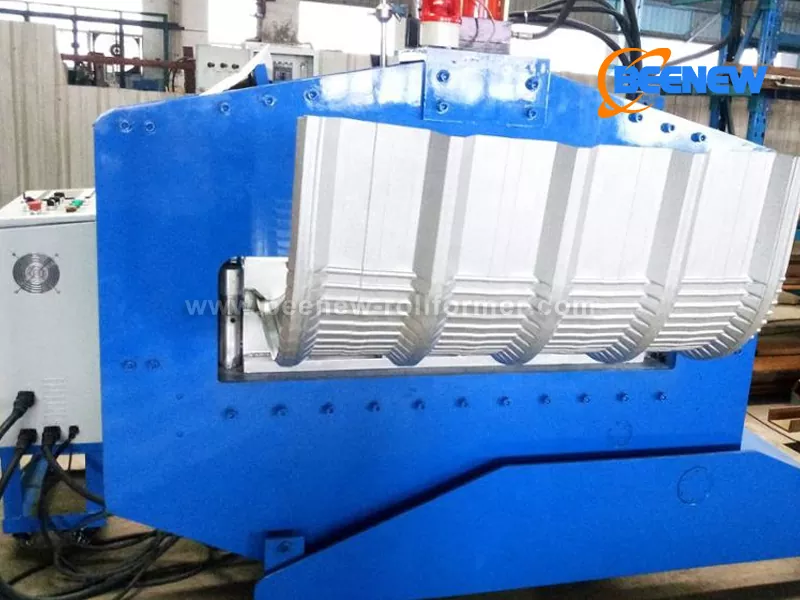

Arch Roof Forming Machine

Arch roof forming machine is another brand of Beenew Machinery's main product, it is the auxiliary machines for metal roof roll forming machine or aluminum sheet forming machines, can form straight roof sheet into different arc shape.

Send Inquiry

An arch roof forming machine is specialized equipment used in construction to shape metal sheets into arched or semi-circular forms, ideal for applications such as roofing and wall structures. These machines are commonly employed in various industrial construction projects, including factories, warehouses, garages, and other large-scale buildings.

Parameter Description

|

Items |

Parameter |

|

Aluminum Sheet Thickness |

0.7-1.0mm |

|

Forming Steps |

3steps |

|

RollerMaterial |

45# steel, coated with chrome |

|

Driving Motor |

4KW |

|

Servo Motor |

2KW |

|

Material Width |

416mm effective width |

|

Power Supply |

380V/50HZ/3Ph (can be specified by user) |

|

Cutting Type |

Hydraulic cutting, no slug cutting |

|

Curving Radius |

min. positive arc is 3m,Minimum negativearc radius is 6m |

|

MaterialofCutting Tool |

Cr12 |

|

Control System |

PLC with touch screen |

|

Machine Net Weight |

1800KG |

Arch Roof Forming Machine Details

Gear/Sprocket driving

Rollers manufactured from 45#, CNC lathes, hard Chrome Coated

Shafts Diameter=approx. ф75mm, Precision Machined

Main motor: 4KW, 1 unit

Servo motor: 2KW, 1 unit

Hydraulic cylinder: 4 units

Hydraulic unit, one set (2.2KW)

Curving line speed: approx. 15m/min.

PLC Control System

Combined with: PLC(Schneider), Inverter (Schneider), Touch Screen(Schneider), Encoder(Omron), etc

Arch roof forming machine is available curving YX50-416 straight panel

For straight panel: when aluminum material thickness is 0.9mm, min. positive arc is 500mm (pre-paint material arc is difference with aluminum)

Arching Roof Sample

Standing seam roof after curved is smooth, without bump, the arch radius is adjustable at specified range. But only good arch roof forming machine can process good effect arching roof, no bump no leakage.

English

English lugha ya Kiswahili

lugha ya Kiswahili  Монгол хэл

Монгол хэл  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Italiano

Italiano  한국어

한국어  Malay

Malay  हिन्दी

हिन्दी  Türkçe

Türkçe  العربية

العربية  Indonesia

Indonesia  تمل

تمل  український

український  فارسی

فارسی  Latine

Latine  Azərbaycan

Azərbaycan