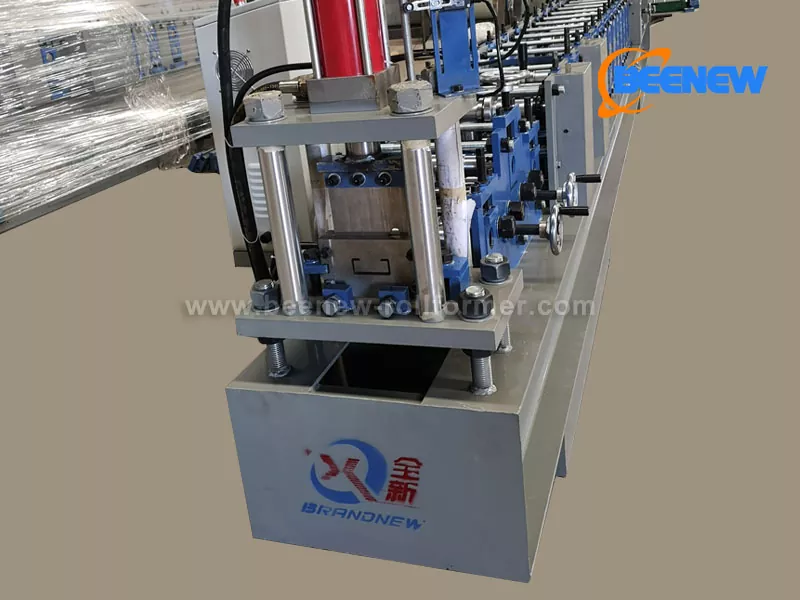

Purlin Roll Former

Send Inquiry

Product Parameter

|

Item |

Parameters |

|

Material Thickness |

1.5-2.0mm |

|

Feeding Width |

125-422mm |

|

Driving Motor |

11kw |

|

Hydraulic Station Power |

5.5kw |

|

Roller Material |

45# steel, heat-treated, hard chrome coated |

|

Shaft Diameter |

70/55mm |

|

Forming Station |

13 stations |

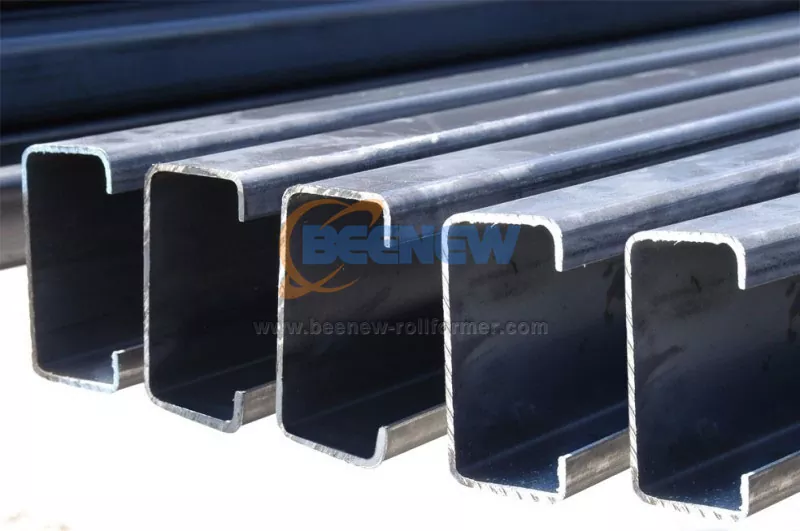

Product Picture

Features

The purlin machine can form the material into the required purlin profiles, such as C, Z or U shapes. This technology ensures high precision, efficiency and consistency in production. Beenew purlin roll former with high technology ensuring the above features and also with a high degree of automation. Just enter the number and length of purlins you require. The PLC control system can then run the machine automatically.

Details

The whole purlin roll former consist of guiding and leveling device, pre-shear and punching device, main rolling mill, post shear, and PLC cabinet.

-Guiding and leveling device: sheet introduction device, adjustable guiding device on both sides, leveling rollers and other components. Adopting the structure of upper three and lower four leveling rollers for leveling.

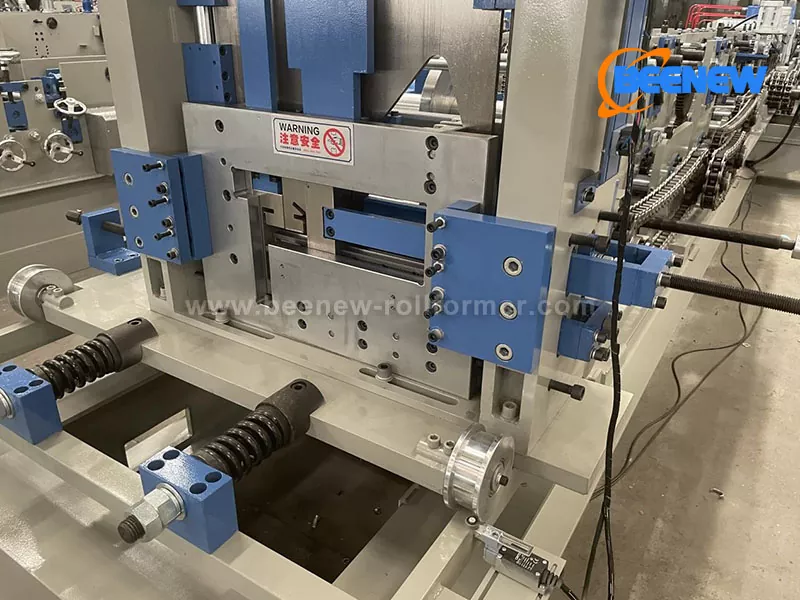

-Pre-shear and punching device:

Hydraulic front shear for cutting off tails;Hydra-punching device requires stopping while cutting. The number of punching molds is customized according to the customer's production requirements

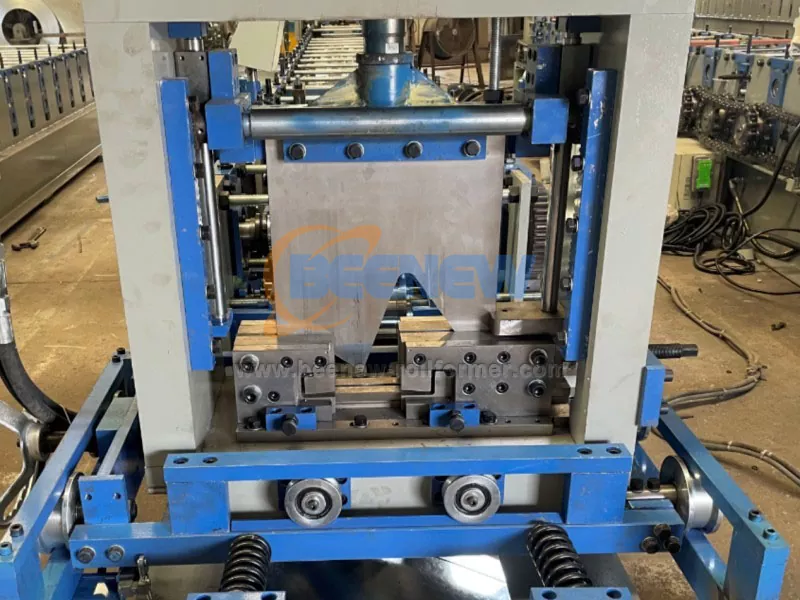

-main rolling mill: 13 stations for forming; All shafts and rollers are solid and fine processed; If the strength and thickness of the material to be pressed is special, the material of the rollers will be made of mold steel with higher strength and special treatment.

-post shear: Shearing after forming; Universal shear, three-blades structure, blade width and height adjustable; blade material CR12MVO;

-PLC cabinet.

The whole purlin roll former is controlled by PLC with human-machine interface. The operator runs automatically through the set program (programmable control) and monitors the control process, realizing the operator to control the production line and modify the control parameters, and real-time monitoring of the equipment running status, running parameters and fault indication. Digital setting of the length of the parts, the length of the parts can be adjusted. Real-time monitoring of equipment operating status and fault indication.

English

English lugha ya Kiswahili

lugha ya Kiswahili  Монгол хэл

Монгол хэл  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Italiano

Italiano  한국어

한국어  Malay

Malay  हिन्दी

हिन्दी  Türkçe

Türkçe  العربية

العربية  Indonesia

Indonesia  تمل

تمل  український

український  فارسی

فارسی  Latine

Latine  Azərbaycan

Azərbaycan