Roller Shutter Door Making Machine

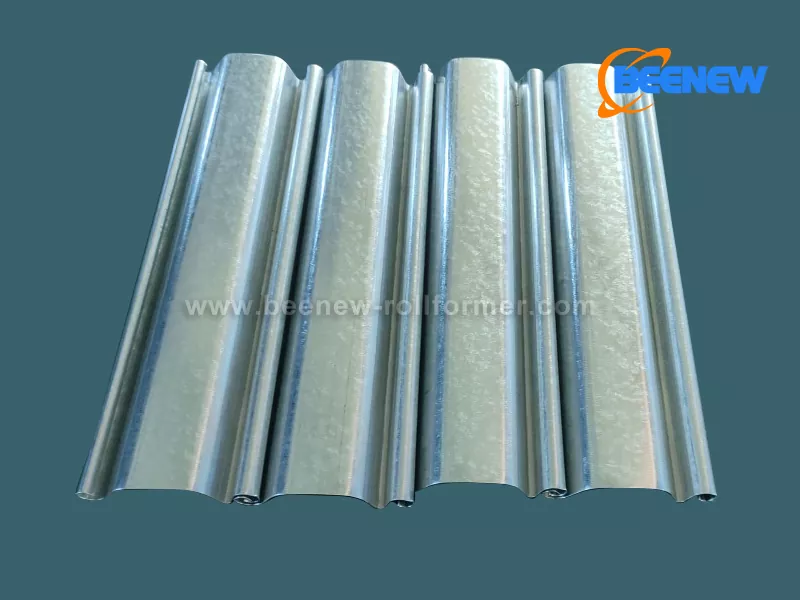

The roller shutter door structure system typically includes four main parts: the roller shutter door, roller shutter door rail, roller shutter door bottom profile, and roller shutter tube. Xiamen Beenew Machinery offers complete roller shutter door making machines for all of these components. Feel free to contact us for more information or to discuss your specific needs.

Send Inquiry

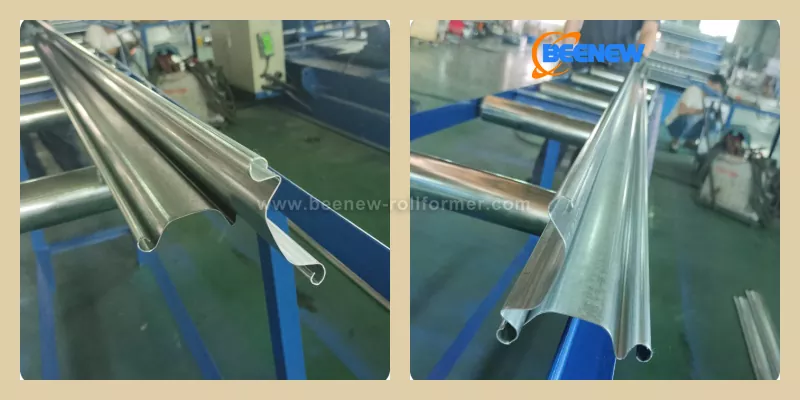

The roller shutter door making machine is designed to ensure the safety and reliability of the roller shutter door system, preventing any risk of the door falling down after the strips are joined together. It’s essential for the joint position of each shutter door strip to be accurate. If the joint size is too small, there’s a danger of the roller shutter door falling, while an excessively large joint size may cause strokes, making it difficult to insert one piece of the shutter door strip into another. To prevent these issues, we carefully adjust the roller shutter door making machine before container loading in our factory.

Parameter Description

|

Items |

Parameter |

|

Aluminum Sheet Thickness |

0.7-1.5mm |

|

Forming Steps |

14steps |

|

RollerMaterial |

45# steel, coated with chrome |

|

Driving Motor |

5.5KW |

|

Hydraulic Cutting Power |

2.2KW |

|

Material Width |

125mm |

|

Power Supply |

380V/50HZ/3Ph (can be specified by user) |

|

Cutting Type |

Hydraulic cutting, no slug cutting |

|

Tolerance |

±1.5mm |

|

MaterialofCutting Tool |

Cr12 |

|

Control System |

PLC with touch screen |

|

Machine Dimension |

5920*1250*1350mm |

|

Machine Net Weight |

2600KG |

Machine Features

The roller shutter door making machine line consists of several key components, including an uncoiler, feeding part, main roll forming system, hydraulic cutting system, and product receiving table, all working together to produce high-quality roller shutter doors.

Machine Key Specifications

Forming Mold: Made from GCr15 molding steel, vacuum quenched to HRC60-62°, and precision-machined with a CNC lathe for high accuracy.

Shaft Material: Constructed from 40Cr steel, processed with CNC lathes, heat-treated, and coated with a 0.04mm hard chrome layer, providing durability and rust prevention.

Driving Mechanism: Features a main motor combined with a chain sprocket drive and approximately 14 forming steps.

Main Motor: 5.5KW with frequency speed control for optimized performance.

Control System: PLC-controlled for precise cutting length, piece count, and adjustable machine line speed.

This roller shutter door making machine is special manufactured for producing rolling shutter doors for industrial plants, warehouses, supermarkets, and shopping malls. Xiamen Beenew Machinery has 27 years experience on kinds of roll forming machines for different industries, we are focus on providing long-lasting and reliable roll forming production line as buyer needs.

English

English lugha ya Kiswahili

lugha ya Kiswahili  Монгол хэл

Монгол хэл  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Italiano

Italiano  한국어

한국어  Malay

Malay  हिन्दी

हिन्दी  Türkçe

Türkçe  العربية

العربية  Indonesia

Indonesia  تمل

تمل  український

український  فارسی

فارسی  Latine

Latine  Azərbaycan

Azərbaycan