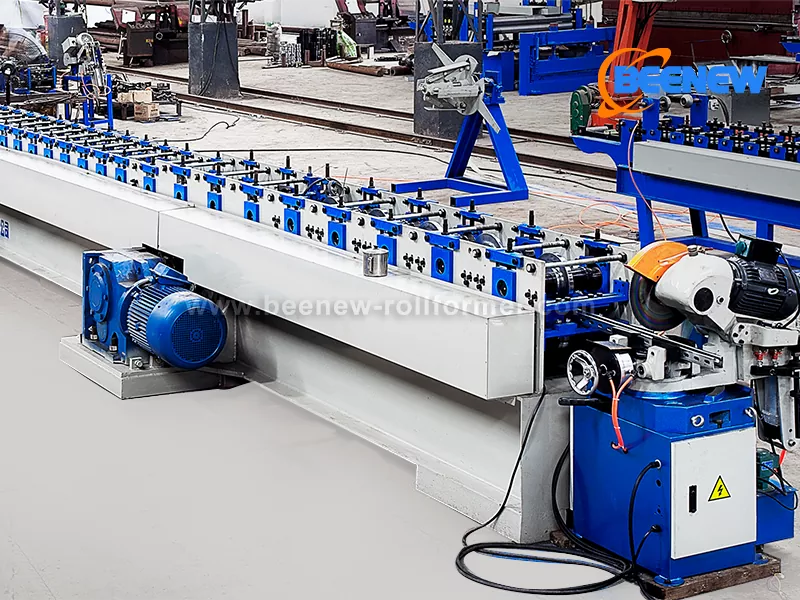

Stud and Track Roll Forming Machine

Send Inquiry

Beenew stud and track roll forming machine are of high-quality and are essential for creating components that play a crucial role in various applications. Steel stud primarily used to support and secure the main parts of equipment, serve as a pivotal connecting element. Tracks, on the other hand, are made from metal or other materials and are designed as grooves or ridges. They are crucial for bearing, securing, and guiding moving devices or equipment while minimizing friction.

The quality and installation of stud and tracks are paramount as they ensure the stability and durability of the entire structure they support. The products manufactured by Beenew stud and track roll forming machine boast precise lengths, accurately positioned holes, and smooth cuts, ensuring seamless operation. This eliminates any worries regarding the quality of the finished products, providing you with complete confidence in their performance and appearance.

Beenew Stud and Track Roll Forming Machine Parameter

|

Item |

Parameters |

|

Material Thickness |

0.8-1.2mm |

|

Driving Motor |

4kw |

|

Forming Station |

12stations |

|

Roller Material |

#45 steel |

|

Shaft Diameter |

65mm |

|

Hydraulic Station Power |

4.0kw |

|

Cutting Length Precision |

±2mm |

|

Control System |

PLC |

Beenew Stud and Track Roll Forming Machine Feature

This Beenew stud and track roll forming machine is specifically designed to handle the production of U-channel steel and L-shaped angle steel, combining the functionality to manufacture both specifications within a single, compact unit. This dual-capability machine not only saves space but also simplifies the manufacturing process, allowing for seamless switching between production modes without the need for extensive downtime or equipment changes.

The stud and track roll forming machine’s compact design is ideal for facilities with limited space but high demands for productivity and efficiency. Despite its small footprint, it does not compromise on performance. The operation speed of the machine is impressively fast, enhancing throughput and reducing cycle times significantly.

Precision is key in metal forming, and our machine excels in this aspect with its precise punching capabilities. Each punch is executed with exacting accuracy, ensuring that every piece meets strict quality standards. Additionally, the machine is equipped with a servo-driven follow-shearing device, which allows for rapid and continuous cutting. This feature eliminates the need for stopping between cuts, thereby greatly increasing production efficiency.

Beenew Stud and Track Roll Forming Machine Details

The stud and track roll forming machine is equipped with a servo follow-shearing system, a feature that sets it apart from traditional hydraulic shearing mechanisms. This innovative technology utilizes a servo motor to control the shearing action, providing several distinct advantages over conventional systems. The servo follow-shearing system allows for extremely precise cuts at high speeds. Unlike hydraulic shears, the servo system is directly controlled with electrical signals, enabling quicker response times and faster cutting cycles. Servo motors provide consistent power output and precise control over the shearing blades, ensuring uniformity in every cut. This consistency is crucial for maintaining high-quality standards in production runs. Also, the stud and track roll forming machine is more energy-efficient when equipped with servo motor. They only consume power during the cutting action, whereas hydraulic systems require the pump to be continuously running, leading to higher energy consumption. With fewer moving parts and no need for hydraulic fluids, the maintenance requirements for servo follow-shearing systems are significantly lower.

English

English lugha ya Kiswahili

lugha ya Kiswahili  Монгол хэл

Монгол хэл  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Italiano

Italiano  한국어

한국어  Malay

Malay  हिन्दी

हिन्दी  Türkçe

Türkçe  العربية

العربية  Indonesia

Indonesia  تمل

تمل  український

український  فارسی

فارسی  Latine

Latine  Azərbaycan

Azərbaycan