Fence Panel Making Machine

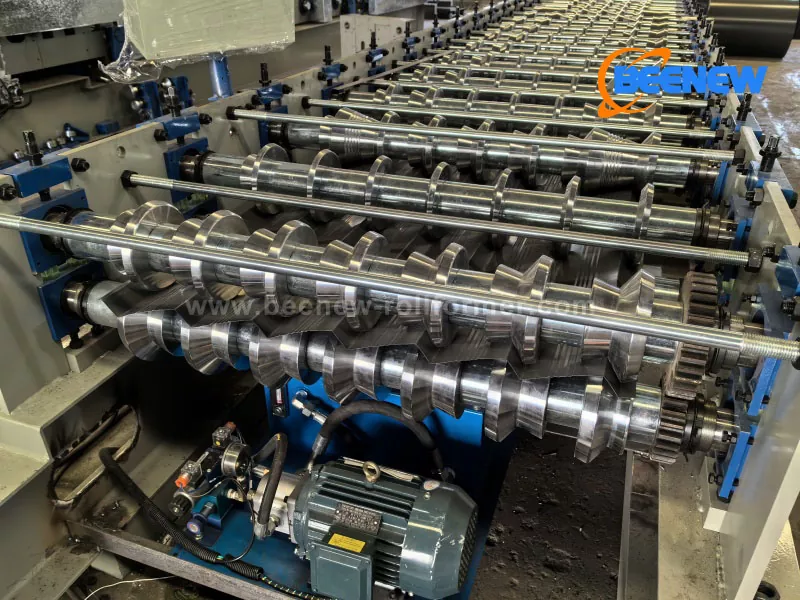

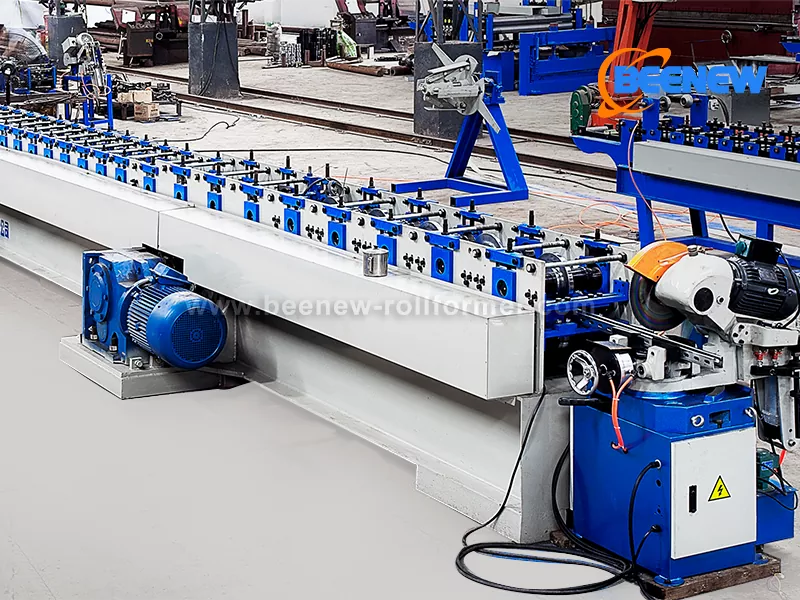

Fence panel making machine is designed to create metal fencing products efficiently and accurately. This machine utilizes a continuous manufacturing process that transforms flat metal sheets into various fence profiles after being formed by a series of rollers that progressively shape the material.

Send Inquiry

Product Parameter

|

Item |

Parameters |

|

Material Thickness |

0.3-0.8mm |

|

Feeding Width |

1000mm |

|

Driving Motor |

7.5kw |

|

Hydraulic Station Power |

4kw |

|

Roller Material |

45# steel, heat-treated, hard chrome coated |

|

Shaft Diameter |

70mm |

|

Forming Station |

20 stations |

Features

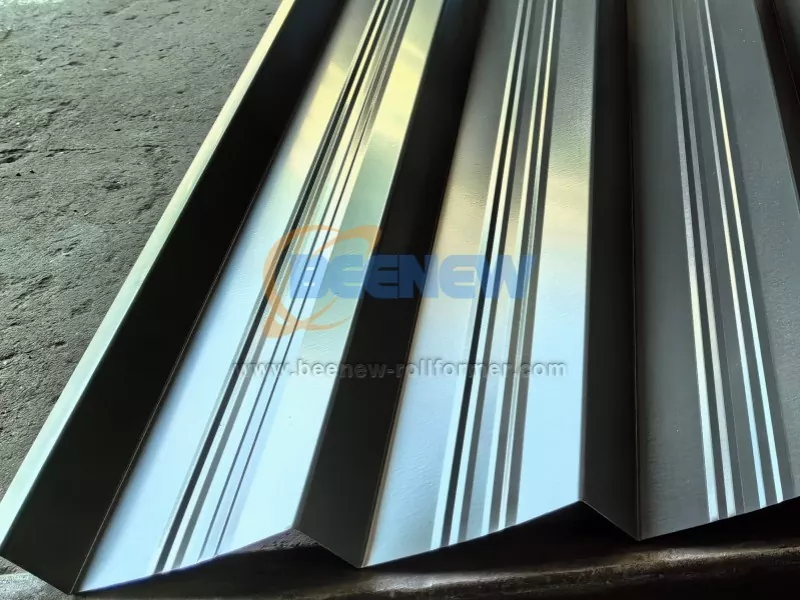

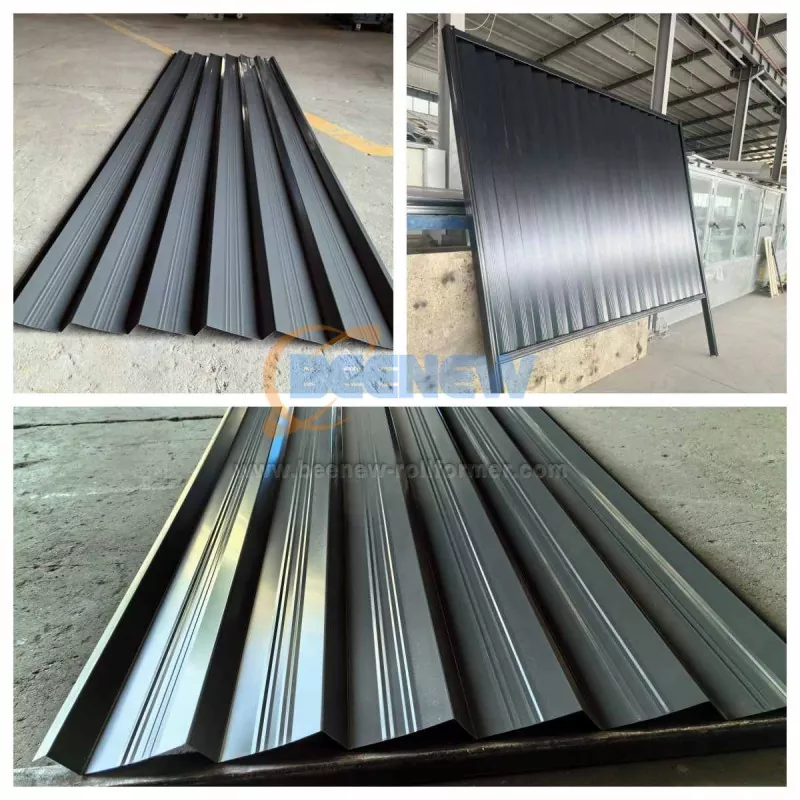

This fence panel machine can produce a versatile version that can be used as a roof wall decoration or as a fence. Its unique stepped version is both aesthetically pleasing and effective in adding strength to the panel. It can be well protected against bad weather and protect our house property. In addition, each step has a compression rib, which makes the layout beautiful and vivid and at the same time increases the strength of the steel plate.

Compression Rib Effect:

Details

The roll forming process ensures high precision and uniformity in the dimensions of the final product.

These machines are capable of producing a variety of fence designs, as required by customer or meet specific market requirements. Metal fence roll forming machines are favored for their speed, efficiency, and cost-effectiveness, as they minimize waste and reduce the need for manual labor. By automating the fencing production process, manufacturers can ensure consistent quality and meet high-volume demands while optimizing their production capabilities.

The Actual Effect Picture

English

English lugha ya Kiswahili

lugha ya Kiswahili  Монгол хэл

Монгол хэл  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Italiano

Italiano  한국어

한국어  Malay

Malay  हिन्दी

हिन्दी  Türkçe

Türkçe  العربية

العربية  Indonesia

Indonesia  تمل

تمل  український

український  فارسی

فارسی  Latine

Latine  Azərbaycan

Azərbaycan