Channel Roll Forming Machine

Beenew channel roll forming machine is an essential industrial tool utilized in the production of channel-shaped metal profiles, commonly used in construction and manufacturing applications.

Send Inquiry

Product Parameter

|

Item |

Parameters |

|

Material Thickness |

1.0-2.0mm |

|

Feeding Width |

156mm |

|

Driving Motor |

5.5kw |

|

Hydraulic Station Power |

3kw |

|

Roller Material |

45# steel, heat-treated, hard chrome coated |

|

Shaft Diameter |

65mm |

|

Machine Weight |

6 Tons |

Introduction

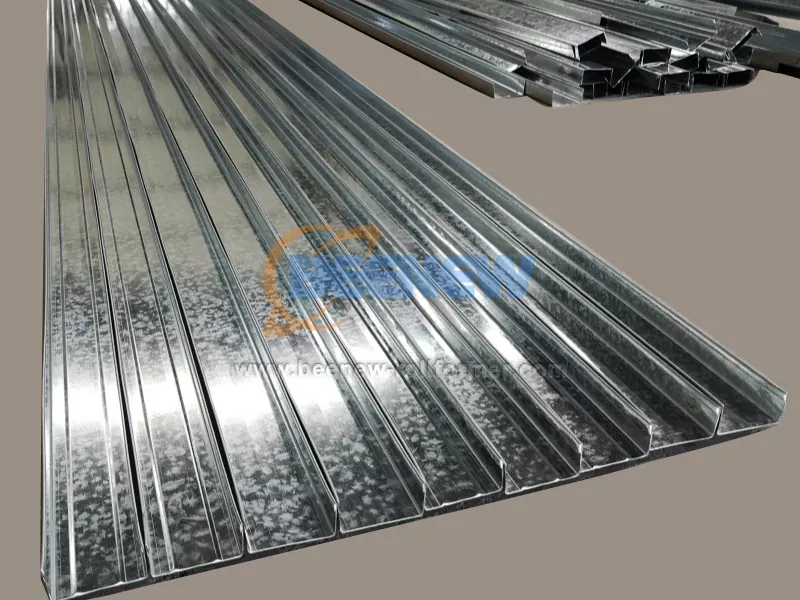

Channel roll forming machine can be designed to form U-shaped, C-shaped or both UC channels depending on customer requirements. These channels are primarily used in structural support, beams, columns, and other areas in steel structure buildings, machinery manufacturing, and electrical equipment. Its good strength and rigidity, along with its lightweight and ease of use, make it widely applied in these fields.

To save time and labor cost, the channel rolling machine is fully automatic. That means from material feeding, punching, forming to cutting, the PLC system will control automatically. You will receive finished products that are dimensionally accurate and aesthetically pleasing without investing too many manpower or complicated operations.

Details

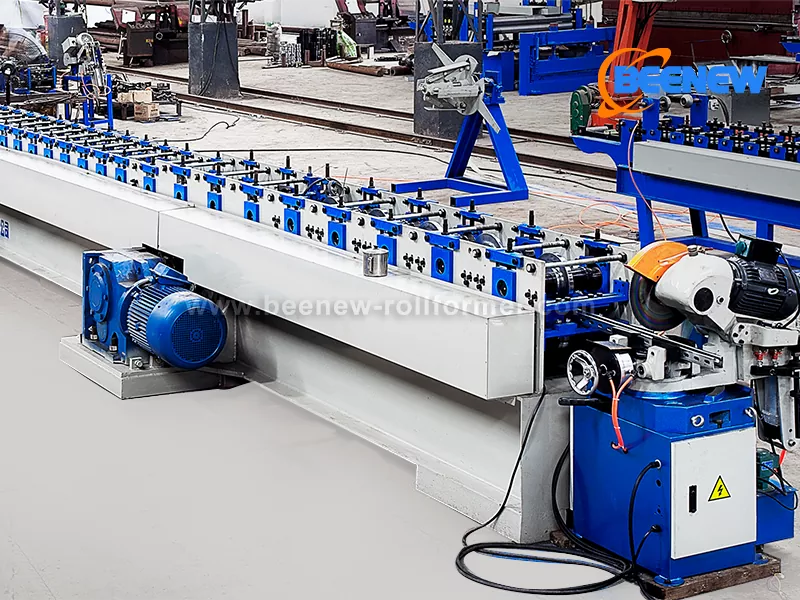

The whole channel forming machine including decoiler, feeding device, roll forming main machine, punching, cutting and stacking.

1, De-coiler

Manual type and hydraulic type for option. Its function is to unwind coiled steel for further processing, such as cutting, shaping, or forming. The de-coiler operates by smoothly and consistently rotating the coil, allowing the steel to be fed into subsequent machinery without causing damage or deformation.

2, Guiding and leveling device

The channel making machine has sheet feeding device and adjustable guiding device on both sides, together with leveling rollers and other components. It adopts the structure of upper two lower three leveling rollers for leveling.

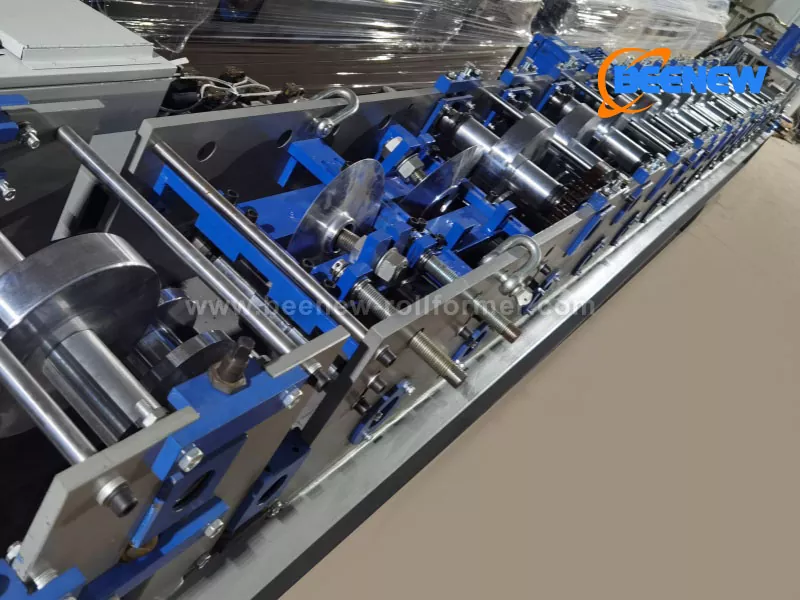

3, Roll forming mill

Consist of several sets of rollers to form channel profile as required. All rollers are fine processed and hard-chrome coated.

4, Punching device

There is a punching device if needed. Hole size and position can both customized. Hydraulic punching device for punching after forming. Stop to cut to avoid openings in the cuts.

5, Stacking

For each set of channel roll forming machine, a set of racks will be equipped. And as customer required, automatic stacker also available.

Pictures of Formed Profiles:

English

English lugha ya Kiswahili

lugha ya Kiswahili  Монгол хэл

Монгол хэл  Español

Español  Português

Português  русский

русский  Français

Français  日本語

日本語  Italiano

Italiano  한국어

한국어  Malay

Malay  हिन्दी

हिन्दी  Türkçe

Türkçe  العربية

العربية  Indonesia

Indonesia  تمل

تمل  український

український  فارسی

فارسی  Latine

Latine  Azərbaycan

Azərbaycan